Guardrails

Working at height legislation OSHA 1910.29 / 1926.502

Features

Advantages

- No damage to the roof membrane.

- Passive barrier that protects all personnel; no training required.

- Extruded 6060 aluminum alloy.

- Range of powder-coated RAL colors.

- Versatility: modular component system for multiple configurations.

- The rail and the sub-rail are made from the same 45mm diameter tube, minimizing the number of components in stock.

- Straight or inclined at 30° according to the architectural requirements.

- Easy installation is ensured thanks to the system‘s low weight and simple plugin connectors.

- Can be installed on flat roofs, parapets, cold deck or standing seam roofs.

Applications

- Maintenance of industrial roofs

- Maintenance of airport roofs

- Maintenance of commercial office and mall roofs

- Maintenance of hospital roofs

- Maintenance of Educational Institutes roofs

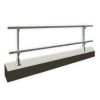

Guardrail fixed on a parapet

Some rooftop configurations include parapet barriers along their perimeter. In such cases, a guardrail to a parapet prevents the need for costly openings into the roof membrane and it also requires substantially less railing than when installed directly to the roof surface. For parapets taller than 500mm, just one railing is necessary. As a result, the cost of the railing system may be reduced by as much as 40%.

The FP guardrail system is straightforward to install. It does not require any welding on site and requires only the basic tools and labor. The components of the railing system can also be completely powder coated in any RAL color, enabling the system to match the building’s color when necessary.

- The uprights must ve fixed every 2m.

- The upright system top height standard is 1100mm.

- The height of the uprights will depend on the height of the parapet wall. Fallprotec could supply any height with an accurate within 1mm.

- A sub-rail must be installed between the top rail and the walking/working surface when there is no parapet that is at least 500mm high.

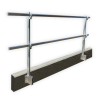

Guardrail wall fixation with offset

The offset upright ensures that the guardrail remains at a consistent height above the edge, regardless of the thickness of the insulation or aluminum cover. This can help to ensure that workers or equipment are protected, even in situations where the edge may be obstructed or obscured by other materials.

- The uprights must be fixed every 2m.

- The parapet’s height ranges from 150 to 500mm, and the guardrail can be installed inside or outside of it.

- The upright with an offset is required to compensate the thickness of the insulation and of the parapet alu cover. The base’s holes allow for either flush or offset installation.

- The angles, end caps, sub-rails, rails, and other components must be added.

- The plates adapt to the different thicknesses of thermal insulation to meet the new requirements of thermal regulations.

Counterweighted guardrail

The counterweighted guardrail must be installed on a flat roof (maximum slope 15°) when it is impossible to fix the guardrail to the structure of the building mechanically; this also preserves the tightness of the roof and eliminates thermal bridges.

- The uprights are placed every 2m along the perimeter of the roof.

- The counterweights are made of PVC for a mass of 12.5 kg. Three counterweights are necessary to ensure stability. The counterweights are equipped with two handling handles.

- The angles, end caps, sub-rails, rails, and other components must be added.